Technical Article

Understanding Hazardous Locations

Many user sites are formally classified as hazardous locations, according to various standards. Other sites may commonly have explosive vapors or gases present, but haven’t been identified as a “hazardous location” due to unfamiliarity with the classification requirements. Regardless, understanding hazardous locations is an important component for pipeline operators to factor in when applying decouplers to their systems. In this article, we’ll take a closer look at how sites are classified as well as its impact on product selection for your application.

What is a hazardous location?

Hazardous (Classified) Locations are defined in the US National Electric Code (NEC), Articles 500-505, and in other international standards such as the IEC, and describe requirements to ensure the safe operation of electrical products used in these locations.

Decisions on the classification of a particular site depend on several factors, most notably:

- Whether ignitable concentrations of flammable gases, vapors, or liquids are considered commonly present or uncommon

- The ease of ignition of the material, considering the gas or vapor type and the temperature of ignition

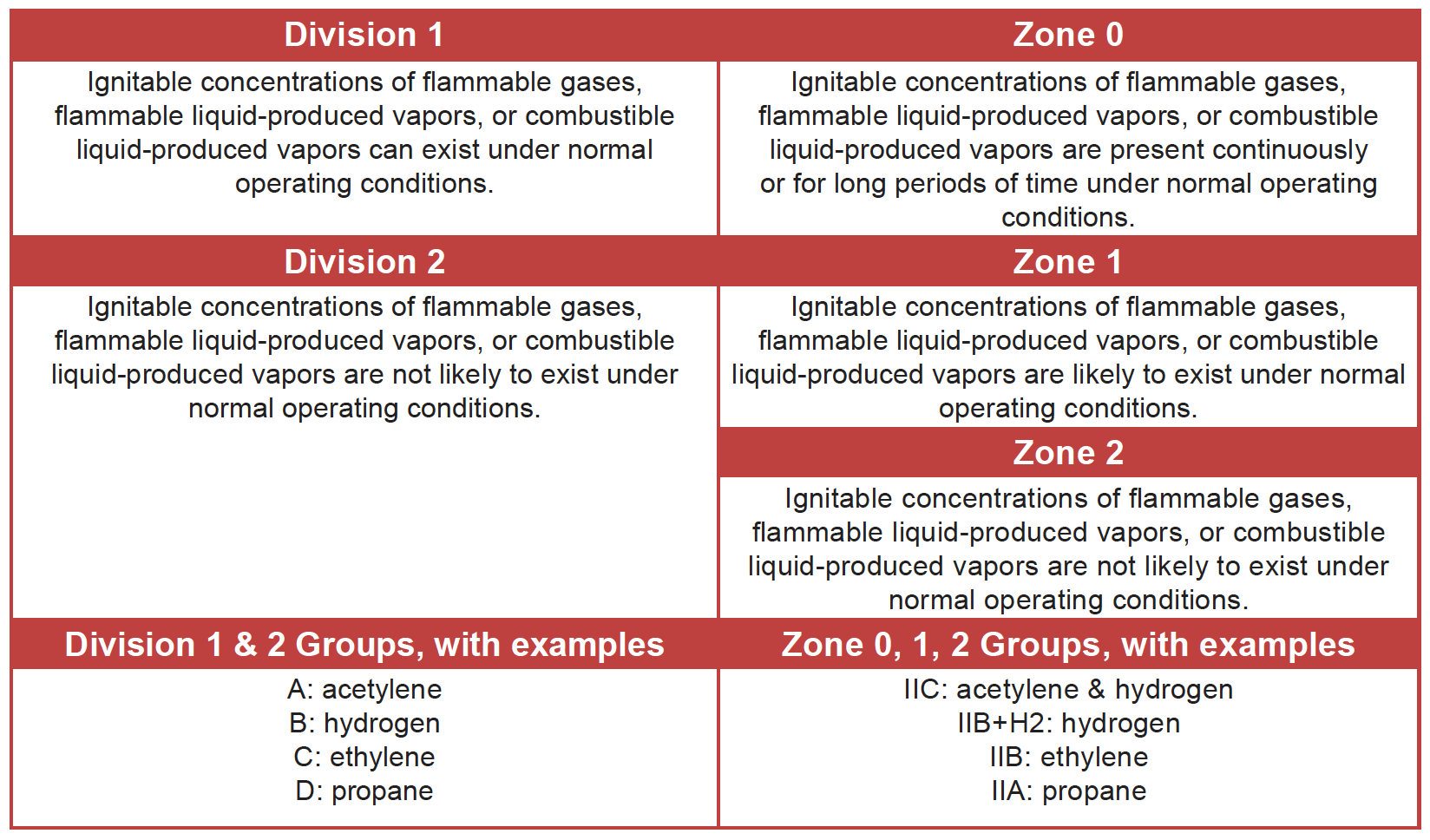

The classification system is summarized below, and compares the NEC Division and Zone methods, where the Zone system is comparable to that found in the IEC. Class I applies to gases, vapors, and liquids, and is broken down into the following areas.

Often Overlooked

Admittedly, this area is not well understood by many pipeline operators, electrical inspectors, or federal regulators. Since the National Electric Code deals with electrical installations, most people don’t realize that this document also defines hazardous locations applicable to applying safety products within the corrosion industry.

A number of pipeline applications in which electrical products are used are non-traditional, hence electrical inspectors and pipeline operators may not identify that NEC 500-505 covers this installation. For example, an over-voltage protection device used on an insulated joint in a cathodically protected gas pipeline is not in a traditional electric circuit, yet it comes under the NEC hazardous location requirements and should be tested and certified by an independent laboratory for this purpose.

Throughout the industry, growing education on the topic of hazardous location is required. This education process involves:

- Identification of a site as a hazardous location

- Classification of the site according to the NEC guidelines

- Selection of electrical equipment that meets the NEC requirements

What if my site isn’t classified?

A report by the American Gas Association entitled “Classification of Gas Utility Areas for Electrical Installations,” number XF0277, expands on Articles 500-505 of the NEC, to further describe how specific gas pipeline facilities would be classified according to this system. Likewise, the American Petroleum Institute document RP-500 provides guidance to the petroleum industry. These documents help to apply the NEC requirements to equipment installations that are not otherwise obvious as being in a hazardous location.

Dairyland Products: Certified For Hazardous Locations

A number of locations where Dairyland products are used could fall under an NEC-defined hazardous location. Typically, this would be a Class I, Division 2, Group D site, such as at an outdoor insulated joint, in a pipeline containing natural gas. Other sites may be classified as Class I, Division 1, such as fueling hydrant pits, underground vaults, or inside buildings, where an ignitable concentration is considered typically present. An electrical inspector may be the party that determines the classification of a given site, using the above criteria, and product selection must factor in the site classification.

A number of locations where Dairyland products are used could fall under an NEC-defined hazardous location. Typically, this would be a Class I, Division 2, Group D site, such as at an outdoor insulated joint, in a pipeline containing natural gas. Other sites may be classified as Class I, Division 1, such as fueling hydrant pits, underground vaults, or inside buildings, where an ignitable concentration is considered typically present. An electrical inspector may be the party that determines the classification of a given site, using the above criteria, and product selection must factor in the site classification.

Dairyland equipment is designed and tested to meet the specific requirements of defined hazardous locations primarily for safety purposes. During the certification process, third party testing laboratories such as Underwriter’s Laboratory (UL) and others, verify that devices used for over-voltage protection and grounding meet the appropriate requirements for each hazardous location classification. Additionally, manufacturers of products for hazardous locations have additional requirements to assure quality production and traceability. These systems are typically based on ISO9001:2015, and have additional ISO/IEC standards that apply, for a manufacturer to achieve full certification for ATEX and IECEx requirements. Dairyland is an ISO9001:2015 certified company ensuring robust quality systems throughout our organization.

Selecting the Proper Decoupling Products

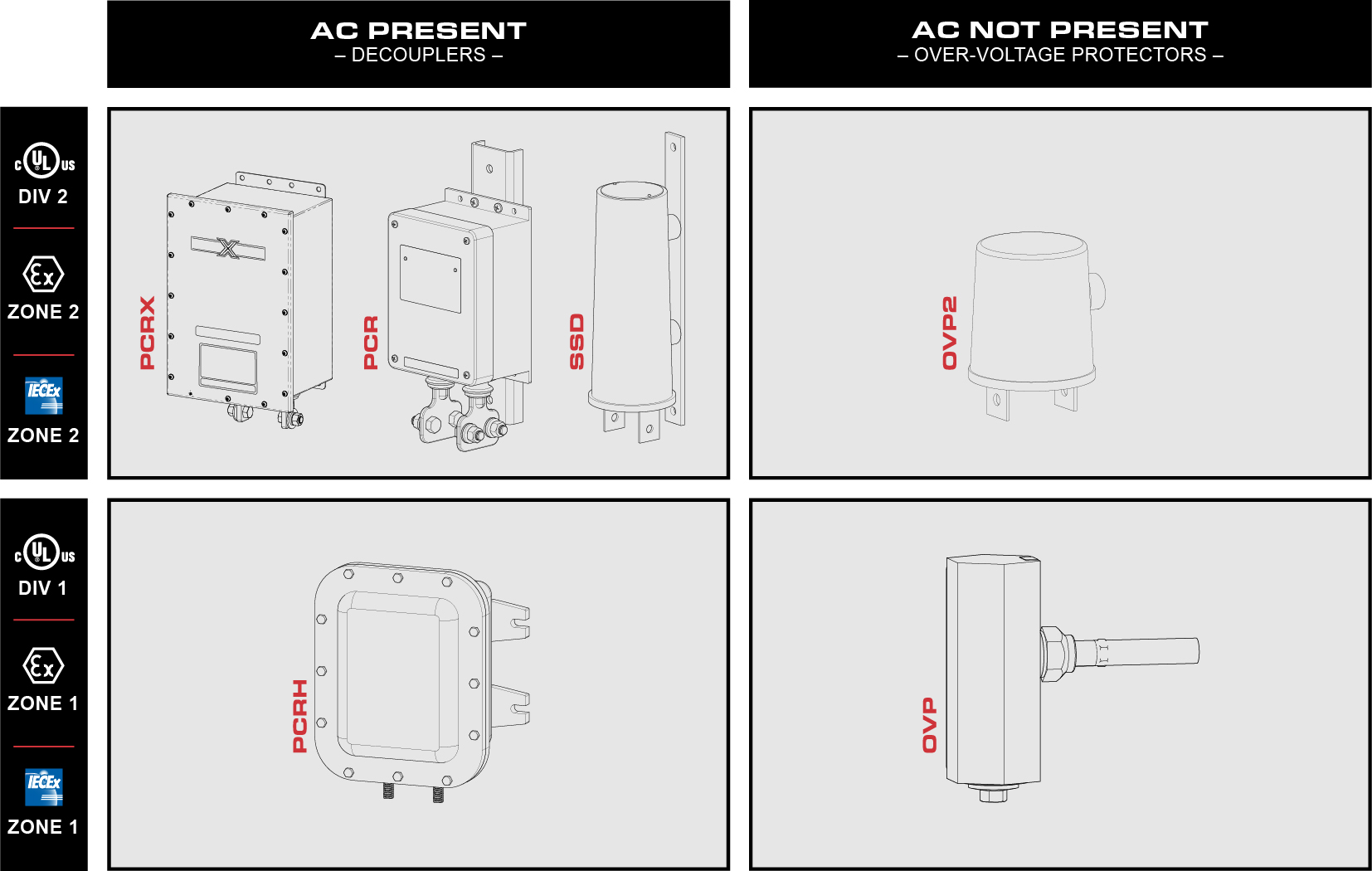

Dairyland offers a variety of decouplers and over-voltage protectors that have been tested and certified to meet the various electrical requirements. The products are UL (United States) and C-UL (Canada) listed for:

- Compliance to hazardous location standards for Division 1 using the “flameproof” method of protection found in UL and CSA standards

- Compliance to hazardous locations standards for Division 2 using the “non-incendive” method of protection found in ANSI/ISA and CSA standards

Additionally, products have been certified by UL/DEMKO and UL for:

- Compliance to international standards (ATEX, IECEx) for Zone 1 using the “flameproof” method of protection found in EN and IEC standards

- Compliance to international standards (ATEX, IECEx) for Zone 2 using the “increased safety” method of protection found in EN and IEC standards

If your site is classified or otherwise treated as a hazardous location, then a product appropriate for this environment should be used, such as the following Dairyland models.

Have additional questions on hazardous locations or choosing the right decoupler for your application? Please contact our technical support team.

Want To Dive Deeper?

Join One of Our Learning Events.

Our event schedule provides you the in-depth product and application training you need to correctly apply Dairyland products.