Working with Dairyland’s UltraBox

Customer Success Stories

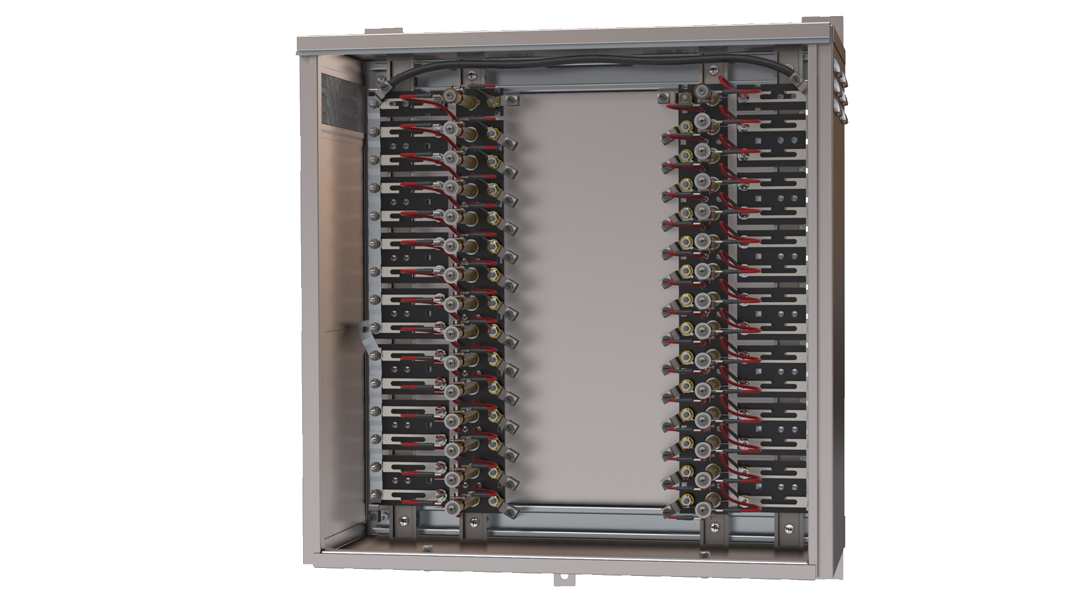

Dairyland introduced its modular junction box—UltraBox—in 2019, and our customers have since applied them in numerous capacities for their unique projects. Now that people have had time to work with UltraBox, we wanted to follow up to find out how they are utilizing the boxes within their system, as well as the reasons why they chose the UltraBox over a more traditional junction box in the first place.

Polycarbonate and Stainless-Steel UltraBox enclosures

Ryan Simpson with Louisville Gas & Electric has purchased both the vented stainless-steel enclosure and the polycarbonate enclosure versions of the UltraBox, and this is what he had to say about how he is using them:

“We use the vented stainless-steel UltraBoxes for bonding connection, anode junction boxes, and multiple return structure connections. This enclosure is my favorite. It is so visually aesthetic that I really love incorporating them into our design. The din rails and modules are great for an organized enclosure. It is also extremely easy to change these components or add more. We have had several sites where we have had to increase the resistance and that was amazingly easy to do by just adding the larger resistor or placing several in series. This box gives so much room to work and install the components. It is our preferred vented box.”

“We also use UltraBoxes with polycarbonate enclosures for grounding connections, insulator bonding, and equipment housing. These boxes are genuinely nice and easy to customize. We prefer to add the components to the UltraBox in the field. The din rail provides an excellent way to mount and organize all the devices and it is extremely easy to add new components later without affecting the seal of the box. We just really prefer these UltraBoxes over other polycarbonate boxes.”

Tim Gubbins with Kinder Morgan has purchased and installed several polycarbonate UltraBox enclosures. He has used them as a rectifier bond box, an anode junction box, and a field junction box. He really likes the plug-and-play ability of the UltraBox, allowing him to configure them in the field and the ability to add whatever component is needed on the fly. When neighboring companies need to add a bond with Kinder Morgan, Tim has requested that they also use an UltraBox in order to keep things consistent.

“One of the benefits of the UltraBox is that it’s incredibly easy for technicians to build and configure them themselves in any location, but Tim also appreciates the option of having the UltraBox preconfigured by Dairyland so that it’s ready to install upon delivery.”

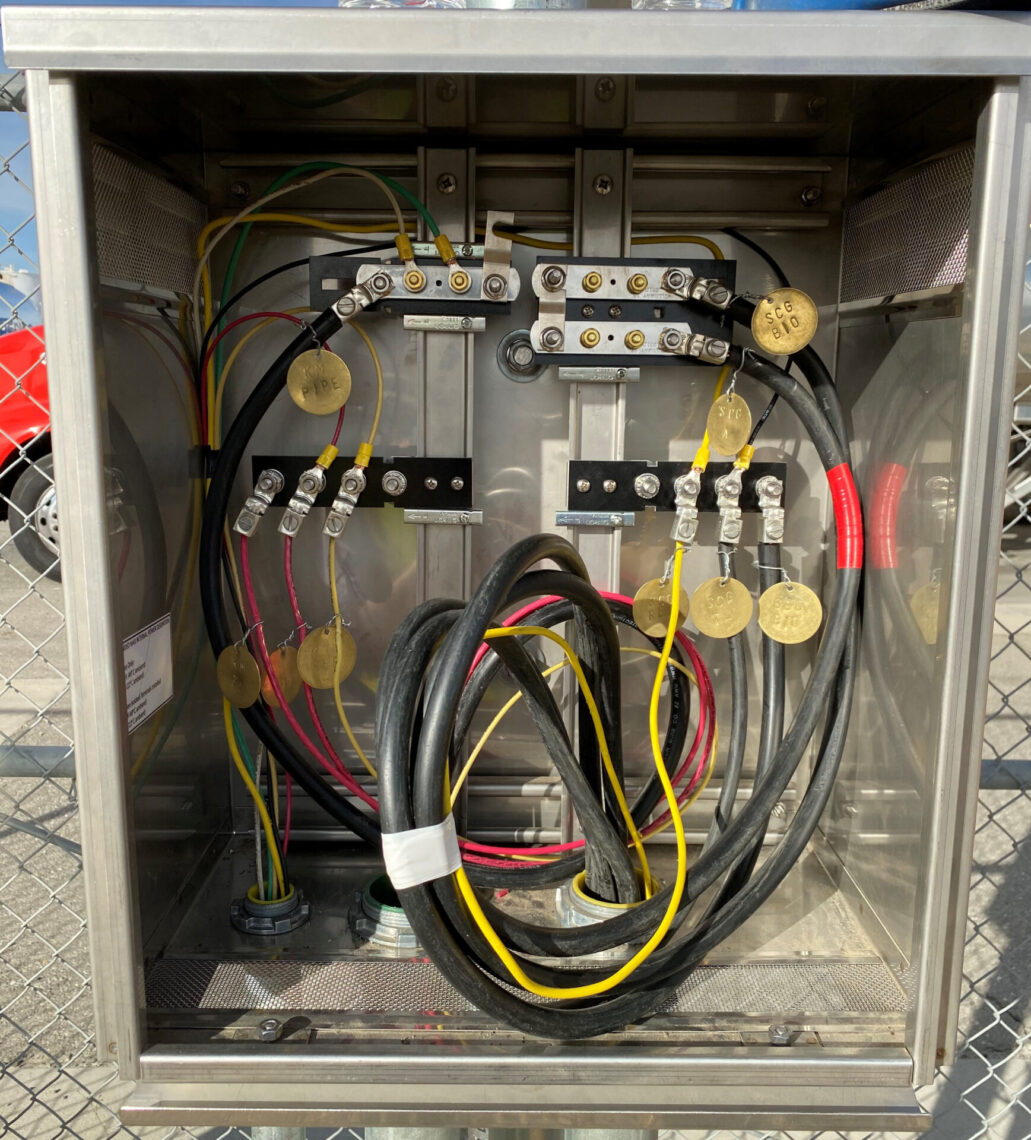

Matt Morales with Southern California Gas first became interested in UltraBox in 2018, when he saw an early iteration displayed at the NACE CORROSION Show for the first time. Since then, he has purchased many vented stainless-steel UltraBox enclosures and has overseen many customized installations. These customized installations allow Matt to add equipment that is not typically found in a standard junction box. He uses the din rail mounting system to attach his components to a blank G10 board, and limited only by his imagination, he can design truly customized boxes. One of the less-common items he is installing in his UltraBox is a reverse current switch that is required for DC interference as per one of the standards of Southern California Gas. The increased depth of the UltraBox provides him more room for these larger, less-common components.

In addition, Southern California Gas is now using UltraBoxes at solar installations to house solar power equipment.

UltraBox used in a Solar Application

From a maintenance perspective, Matt really likes the ability to replace a component after it has gone bad. Let’s face it, a shunt or a resistor is going to fail. To replace them in a traditional junction box, you will need to unscrew the back plate, often uncovering a mess back there. Generally, the wires are jumbled behind the micarta board and require untangling in order to find the one you’re looking for. However, with the UltraBox, you can make the installation nice and clean by having the wires run in a neat order. You also have easy access to all the components, allowing you to quickly replace one without worrying about loosening other wires or component in the process.

UltraBox secured with a padlock

Another key feature of the UltraBox, is the added flexibility to move components at any time. For Matt, this comes in handy when working with large gauge wire where, in some cases, it is easier to move the component to the wire as opposed to manhandling the wire to go to the component. The ability to move a component even a half-inch could make all the difference in the world and lessen frustration in the process. This equates to reduced labor and headaches from a long-term maintenance standpoint for Matt and his technicians.

Matt also appreciates the sturdy construction of the vented stainless-steel UltraBox and the added security it provides. It’s easy to secure the door using the clamping bar at the bottom of the enclosure, locking it in place with two bolts. For even more security, you can add a padlock to the eyelet at the bottom of the enclosure. Another benefit of the vented UltraBox enclosure is that the vents all have a small robust mesh that prevents animals, reptiles, and wasps from gaining access to the box.

Key UltraBox takeaways:

- Completely customizable design that can accommodate solar controls or RMUs.

- Improve efficiency by building the UltraBox in the field to the as-built conditions of the site.

- Compatible for multiple operators to customize to their own specifications.

- Added security from theft, vandalism, and small critters and insects.

- Maintenance-friendly design allows for easily replacement of individual components.

Summary

The title of this article was chosen purposefully to highlight the ways our customers “work with an UltraBox” as opposed to simply just installing an UltraBox. The ability to customize the UltraBox in the field allows the technician the flexibility to adjust the placement of components or modify the design and layout to meet their specific needs and preferences. These real-life examples not only show how people are using the UltraBox, but also illustrate the added ease and flexibility that it offers. If you’d like more information on how the UltraBox can work for you, reach out to our team for a consultation.

Want To Dive Deeper?

Join One of Our Learning Events.

Our event schedule provides you the in-depth product and application training you need to correctly apply Dairyland products.