Technical Article

Shore Based Isolation to Prevent Galvanic Corrosion on Ships

Whenever a marine vessel is connected to AC shore power, a galvanic circuit, which can cause corrosion of the vessel and its drive system components, is established. Anytime there is a direct bond between dissimilar metals in an electrolyte, a galvanic corrosion cell is established. In this application, the direct bond is the grounding conductor in the ship-to shore power cable, the electrolyte is earth and water, and the metals in the marina and marina electrical grounding system are normally different than the metals in a boat.

A simple way to eliminate this corrosion-causing circuit is to install a decoupling device, such as a Dairyland Galvanic Isolator, in series with the safety grounding conductor in the ship-to-shore power circuit. This can be done one of two ways. A decoupling device can be installed by the marina or port operator on the shore side of the circuit or it can be installed on the vessel by the owner. Either installation location will prevent the flow of corrosion-causing galvanic current while retaining the safety features of the grounding conductor, provided an appropriately rated and certified decoupling device is used. This application note deals specifically with preventive measures that can be taken by the marina or port operator.

Effective Grounding Path

When a decoupler is used in the safety grounding conductor of electrical equipment, it must meet certain code requirements. In the U.S., the applicable code is the National Electrical Code (NFPA 70). The most important code sections are 250.4(A)(5) which defines the requirement for “an effective AC grounding path,” and 250.6(E), which allows the use of a certified decoupling device for “blocking the flow of objectionable DC current”. Other countries have similar codes. A key requirement of Section 250.4(A)(5) is that if a decoupler fails, it must fail as a “short circuit.” In the short circuit mode, it must still be capable of meeting all published current ratings. If this requirement is not met, it is not “an effective grounding path”. Dairyland products recommended for this application meet and exceed this criterion. That is, when the Dairyland decoupler recommended for this application is tested to current levels that will cause failure, the product will fail in the short circuit mode and be capable of carrying current well in excess of every current rating (i.e., steady-state current, fault current, and lightning current).

On a related note, decouplers that are installed on a vessel must meet requirements which are defined in American Boat and Yacht Council (ABYC) Standard A-28. The ABYC standard does not require or reference the sections of NFPA 70. However, ABYC A-28 does define a class of galvanic isolators that are considered “fail-safe,” and when tested to assure fail-shorted operation would provide the needed effective grounding. Use on a shore-based electrical system would depend on the manufacturer’s device certification, and whether it allows such use. Dairyland specifically has certification for product use on shore electrical systems covered by the NEC. Other devices defined within A-28 that are not considered fail-safe must have a monitoring system to indicate if the unit is functional, and these types of devices would not meet the shore-based grounding codes and may not be used.

Typical Application

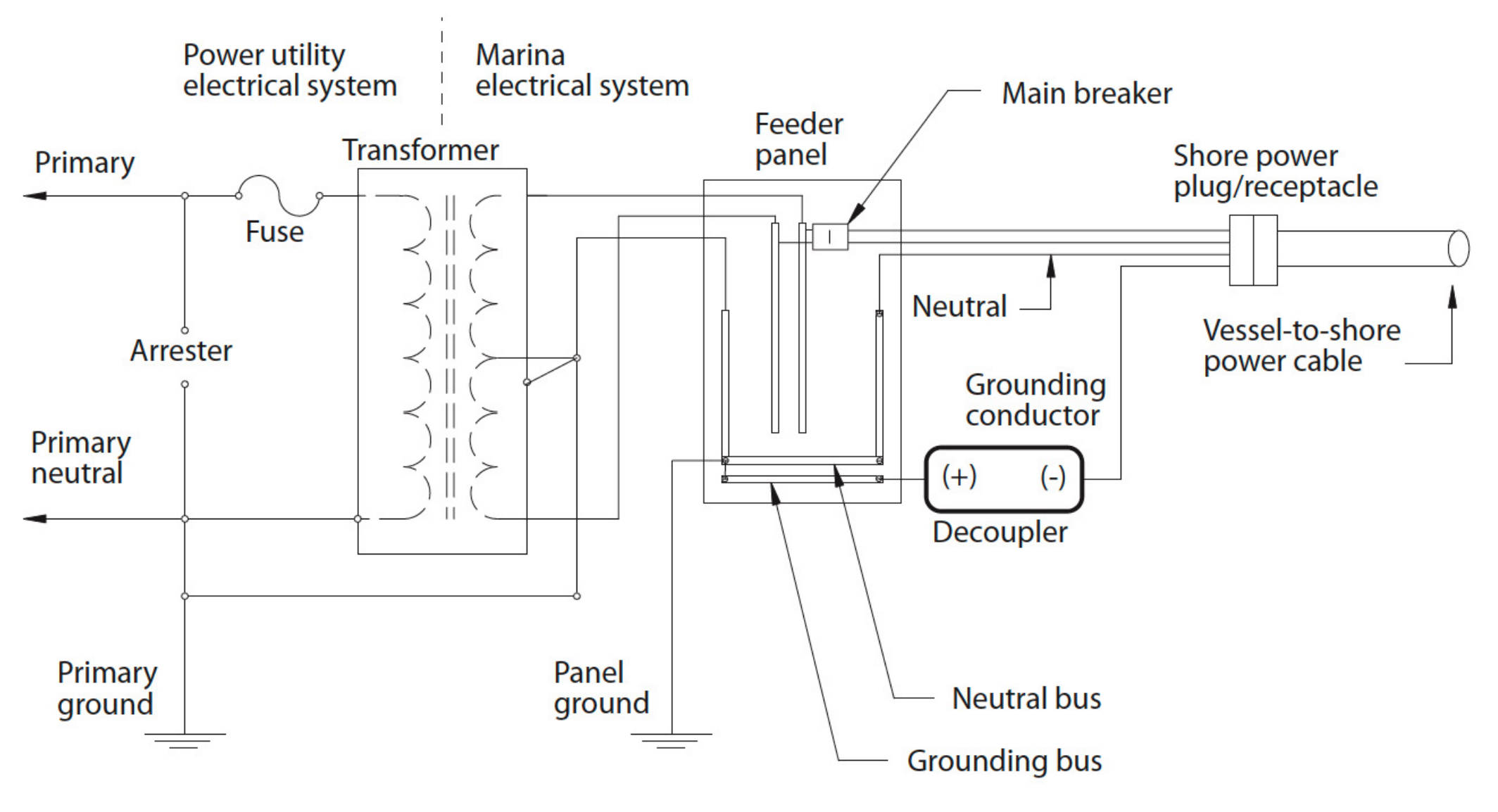

A typical installation for installing a decoupling device on the shore side of a ship-to-shore AC power circuit is schematically illustrated in Figure 1 for a single-phase service. Similar criteria apply to other types of single- phase service or three-phase services that utilize a safety grounding conductor. The typical device used is one of the Dairyland Galvanic Isolator models chosen for the appropriate shore cord current rating, which also indirectly selects the AC fault current rating. When placed in series in the grounding conductor that feeds the shore cord receptacle, the Dairyland Galvanic Isolator will block corrosion current, allow any AC to flow, and will switch to the shorted mode as needed to address AC faults or conduct lightning current.

AC Fault Current Rating

The key rating of a decoupler or galvanic isolator used for this application is the AC fault current. The ABYC standard relates steady-state AC current ratings to AC fault ratings, however it is the fault rating that is most important. If a Dairyland Galvanic Isolator is selected based on matching its steady-state current rating to the shore cord rating, and a user feels that there is a higher AC fault current available at this point in the system, a larger fault-rated Galvanic Isolator may be needed. The Dairyland product fault rating should exceed the available system fault current, considering the current magnitude and the time duration of the fault. There are three typical methods for determining fault current if this value has not been provided.

1. AC fault current may be controlled by the current- time clearing characteristic of the circuit breaker for the circuit of interest and selecting a device with ratings that exceed the breaker curve settings. If chosen correctly, the breaker will trip before the device ratings are exceeded.

2. The fault current may indirectly be determined by examining the current-time capability of the grounding conductor size into which the Dairyland device will be inserted and selecting a device that has ratings that exceed the wire capability ratings. Such data can be determined from cable short circuit rating charts, such as by ICEA in standard P-32-382-2007.

3. The most conservative approach is to determine the maximum fault current available at the upstream transformer terminals and rate the Dairyland device to meet that value. Transformer nameplate data contains the appropriate information to calculate this value.

If assistance is needed with any of these methods, or with other rating and application aspects regarding Dairyland Galvanic Isolators or decouplers, please contact us.

Figure 1. Typical Installation of a Shore-Based Galvanic Isolator

Notes:

- Decoupler: A DC isolation/AC coupling device. Recommended: Galvanic Isolator models by Dairyland. Listed per NFPA 70, Article 250.4(A)(5), 250.6(E).

- Do not install the decoupler in series with the secondary neutral.

- Observe polarity marks when installing the decoupler.

- There cannot be any bond between the neutral conductor and teh grounding conductor downstream of the decoupling device because this would bypass the decoupler.

- One decoupling device per vessel is recommended, (to prevent bonding the vessels to each other through the grounding conductors, which would establish a vessel-to-vessel galvanic corrosion cell.) However, this will depend on whether this feeder panel serves multiple vessels and if the decoupler can be located at a pedestal or junction box so that the vessel of interest is isolated from all other grounds/vessels.

- Similar installation procedures apply to other single-phase and three-phase services that utilize a safety grounding conductor.

- If there is any question as to proper installation procedures, contact Dairyland for assistance.

Want To Dive Deeper?

Join One of Our Learning Events.

Our event schedule provides you the in-depth product and application training you need to correctly apply Dairyland products.